08 November at 06:00PM

Examining A Real World Example: An Agile Approach Leads to Project Success

An Agile Airplane?

Agile is well known in the software world, but it has wider applications in other industries. As a project management approach, it might not be ideal to apply it to building a condo or a new factory. Yet, in industries where products undergo multiple iterations before being customer-ready, an agile approach can lead to project success.

Project management principles and techniques feature heavily in aircraft design. An airplane can be agile, which is how Boeing developed the 777 in the 1990s and the 787 Dreamliner in the early 2010s. There are other circumstances when project management techniques aren't fully utilized and projects fail to meet market and customer standards. Let’s look at two examples from Boeing where the agile approach was used—the 777 and the 787—successfully. Then, let’s examine the 737 MAX and where an agile approach could have turned the project around.

Successfully Applying Agile Principles to the 777 & 787 Dreamliner

The development of the Boeing 777 had two main requirements. First the availability of new technology—computer-aided design (CAD)—was key. The second requirement was people management.

These requirements are best described using fail fast/prototyping and team of teams.

Fail Fast/Prototyping: Pre-CAD, planes were designed via 2D drawings (drafting) and were either inspected using actual prototypes that would be built and sent for physical fit-checks, or entire aircrafts would be assembled and adjustments would be executed on the spot. Inevitably this would be expensive when adjustments were required.

The 777 was the first airplane to be developed when CAD technology was becoming widely available. This meant that parts being designed all around the world (e.g., wings in X and doors in Y) could be virtually prototyped on a computer. The fit could be checked before having to fabricate any physical parts, and adjustments could be made quickly before fabrication. Errors could be reduced ahead of time or designs could be changed to suit customer requirements after getting feedback on the virtual prototypes. This is a great example of the “Fail Fast” approach in Agile.

|

Photo by RODNAE Productions from Pexels |

Photo by Pavel Chernonogov from Pexels |

Team of Teams: One other interesting aspect of the 777 design was the global nature of the teams designing and building its parts.

Previous planes consisted of parts built by specialists in different departments and integrated by a systems integrator team. As parts were being integrated, thousands of adjustments and changes could be needed. This meant a lot of rework would be generated during the integration stage and different parts could be in competition with each other such as the machine shop or the drafting room.

The 777 program took a different approach to teams. A “traditional” team was established based on the macro part of the plane (e.g., a “Wing” team) but a new approach called “team of teams” was also established. What this meant was the team building the wings were broken into sub-teams who would be responsible for every component part needed to build the wings— a “flaps” team, an “aileron” team, etc.

The Wing team would have full visibility and control of their own components, while also reporting up to the program director who was responsible for the final integration.

Each sub-team was composed of members from different departments, who could work together to design, prototype, and build their part completely independent of other departments. In this way each team could keep the project moving forward without little disruption and easier project flow.

Another important function of the “team of teams” was having in-person meeting updates. The Program Director organized quarterly in-person meetings for the entire 777 team. This included over 10,000 people who would gather in Seattle to review project progress, meet customers, and understand changing requirements. It was also an opportunity to share tips, learn from each other, strengthen relationships, and develop networks.

Taking a Hybrid Approach for the 787

The 787 project is an example of how using two agile principles can work well together. The project used iterations—developing two products based on the same platform, but with differing customer requirements—and delivering value quickly.

Customers—in this case airlines—make specific requests based on their needs. In some cases this means different requirements are needed for airframes or engines—also depending on the maintenance or engine contracts they have. Boeing delivered its first 787 in 2011 to ANA Group Corp. with Rolls Royce engines. Six months later Boeing delivered a 787 with GE engines to Japan Airlines.

While releasing two versions of similar products is not a new thing, it is an example of how Boeing was able to use two different teams in parallel in order to successfully deliver different aircrafts to two customers during similar development cycles.

How Under Utilizing Project Management Techniques Can Lead to Project Failure

In 2018 and 2019, Boeing made the headlines with the tragic crashes of two 737 MAX 8 aircrafts in Ethiopia and Indonesia. The 737 MAX was an upgraded model of a previously available plane that was in service for several years around the world. In other words, changes were made to an already-successful design, in order to create a new product that could be sold to airlines which promised more profitability than older models.

> What changed?

The new plane was using a bigger and more powerful engine which was being added to an existing airframe but positioned higher than the previous engine. This altered the balance of the aircraft. In order to equalize the plane a software system called MCAS (Maneuvering Characteristics Augmentation System) was installed.

> What was the problem?

The subsequent crash investigations revealed there were multiple causes for the disasters and were connected to two areas of project management: Stakeholder Management and Environmental Factors.

Stakeholder Management

The addition of MCAS was not clearly communicated to pilots and even removed from flight manuals during the certification process. Reports showed that during the two incidents the MCAS system activated itself incorrectly and the pilots were forced to manually intervene to recover the aircraft. In both cases, the pilots—key stakeholders—were not informed of the new technology, its capabilities, or how to properly manage in emergency situations.

Photo by Rafael Cosquiere from Pexels

Environmental Factors

Competition can be considered the key environmental factor in this case. In order to compete and deliver quicker, production and training were under utilized. At the time Boeing was facing immense sales pressure from their competitors with the success of the Airbus A320neo. In order to regain market share, production was escalated for the 737 Max 8. Market pressure and the need to deliver meant that the project team had to deliver quickly and missed some key requirements.

> What was the result?

Sadly, there were two avoidable crashes with the loss of 346 lives. Additionally, Boeing suffered financially, paying out US$18.6 billion in compensation, legal fees, cancelled orders, and a 20-month grounding of the aircraft, which was re-approved to enter service by the FAA in mid-November 2020.

Lessons Learned

Whenever you work on a project, think through all aspects carefully. When product or scope changes occur, ensure that all key stakeholders have been updated, and that their needs are taken into account.

Furthermore, always proceed on any project with transparency and honesty. Remember, ethics are a key part of being a project manager. If you feel pressured to hide or obscure unfavourable information, you must speak up. Changes don’t have to end in disaster, instead if they are handled in the correct manner, changes often lead to new and improved products or projects that deliver value to an organization or customer.

Fail fast, team of teams, and iterations are components of agile project management which can help you deal with change successfully.

Agile is neither new, nor confined to software development. Can you apply agile principles in your work? Are you already doing so without realizing?

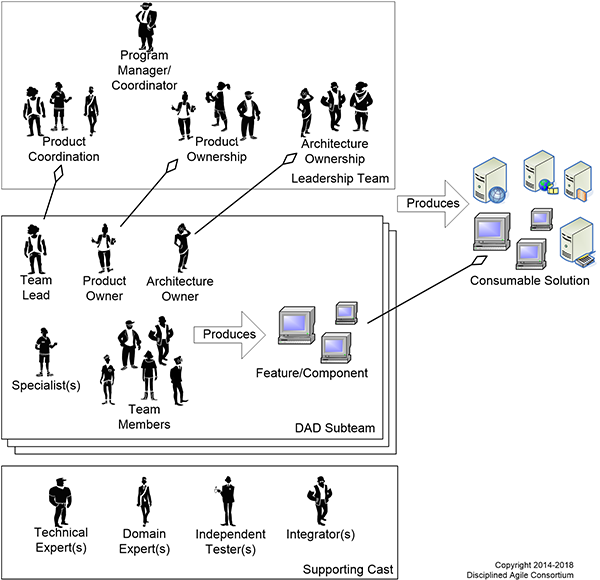

Learn More About Discipled Agile

To learn more about Agile, visit PMI and PMI Toronto websites for more information and details about certification and training. Some sites to consider are:

- Disciplined Agile overview (PMI): https://www.pmi.org/disciplined-agile

- Disciplined Agile Training (PMIT): https://www.pmitoronto.ca/disciplined-agile

- Certify as PMI-ACP: https://www.pmi.org/certifications/agile-acp

For more information on the certification and training program offered at PMI Toronto please visit the Certification and Training section to find out more about the courses offered and upcoming dates.